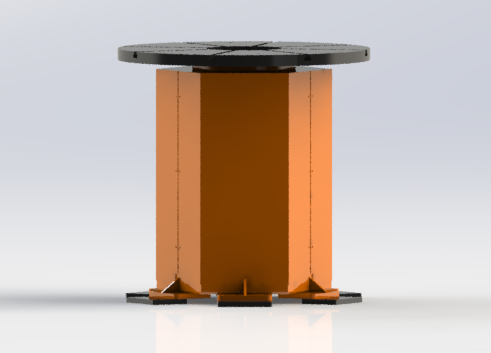

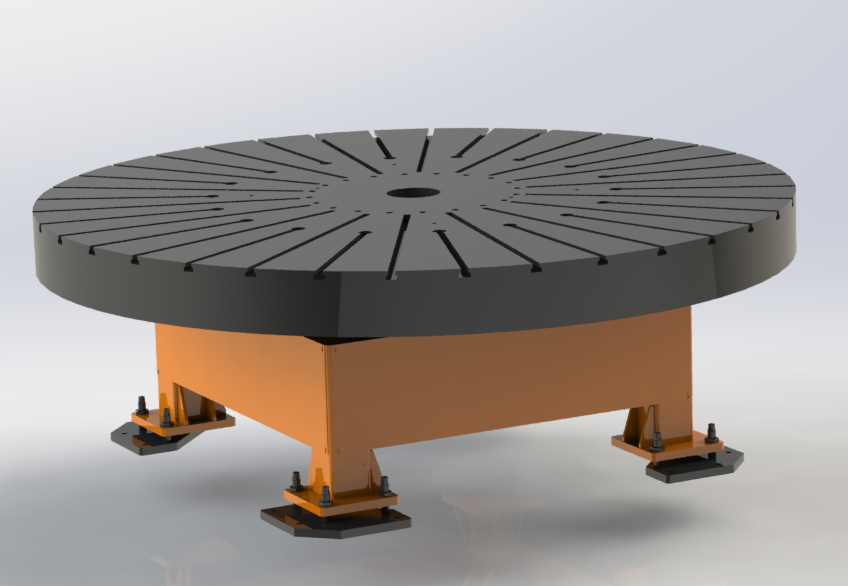

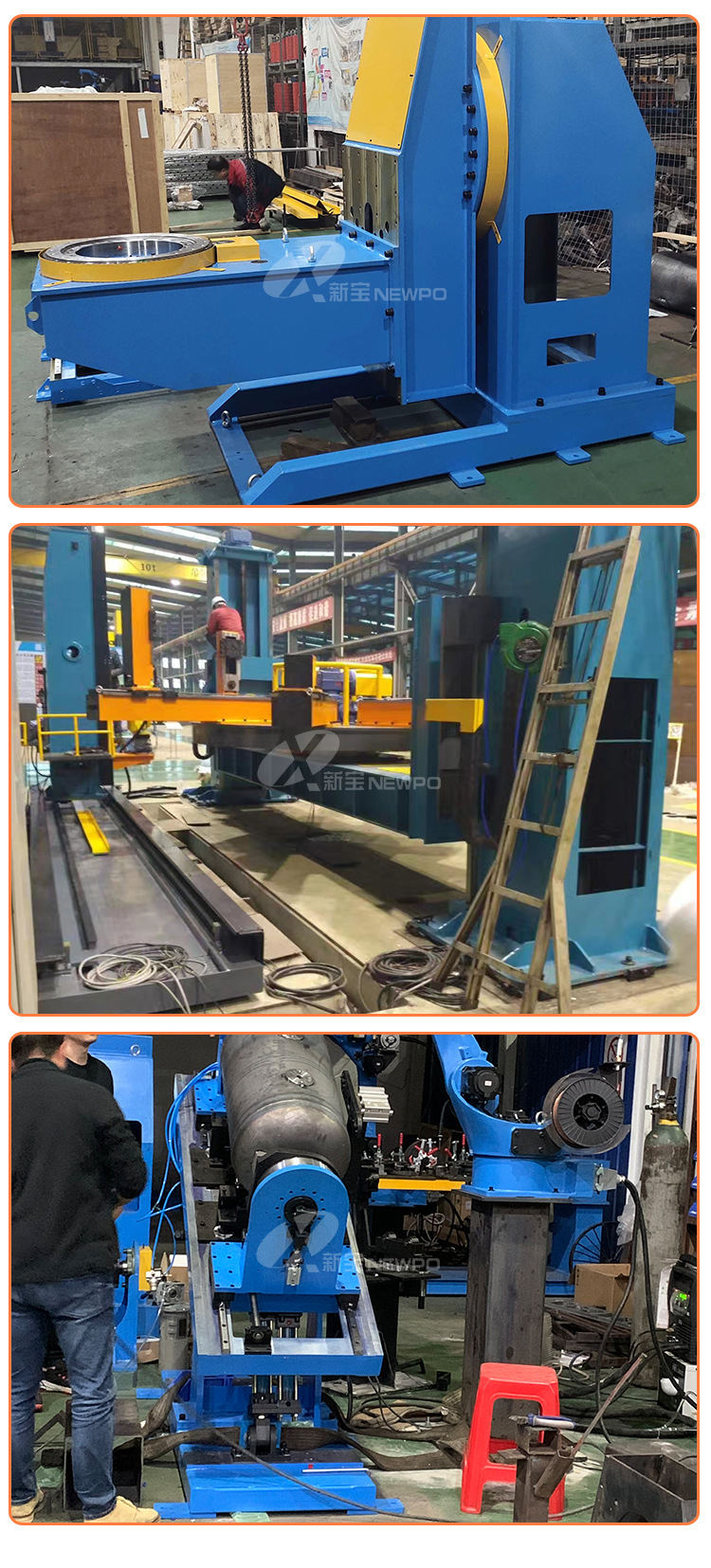

L-type dual axis positioner

- Commodity name:L-type dual axis positioner

- Manufacturer: Xinbao Intelligent

Product Details

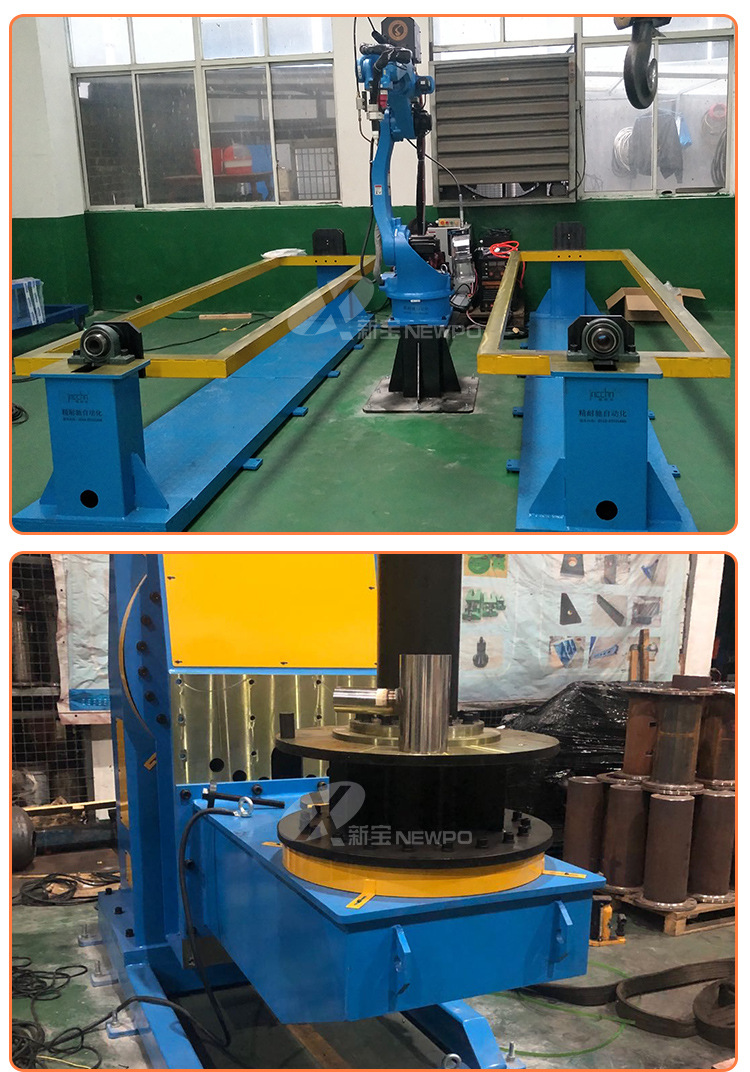

Welding positioner is a device used to drag the workpiece to be welded and move the weld seam to the ideal position for welding operations. Generally speaking, manufacturers of welding operators, roller frames, welding systems, and other welding equipment mostly produce welding positioners; Most manufacturers of welding robots produce welding positioners that are compatible with the robots. However, it is very rare for enterprises that focus on welding positioners as their main products. Severt and Aroson companies in Germany are considered typical enterprises that produce welding positioners. CLOOS from Germany, IgM from Austria, and Panasonic Robotics from Japan all produce welding positioners that are servo controlled and compatible with robots. The following is only an introduction to the type and main parameters of the displacement machine.

Definition:

In China, welding positioners are a young product. Due to the differences in development levels between manufacturing industries, many enterprises' welding stations have not yet been equipped with welding positioners; Meanwhile, related research is also relatively weak. So far, there have been no specialized works to study its definition and classification. It is impossible to standardize its name. The same device may be referred to differently by different companies and individuals. Such as: tire rotation, turntable, flip frame, positioner, positioner, etc. It needs to be given a definition. It has changed the welding operations that may require vertical welding, overhead welding, and other difficult to ensure welding quality. Thus, the welding quality is ensured, and the welding productivity and production process are improved.

Main degrees of freedom

It can be said with certainty that if a positioner drags a welded component and only performs linear motion, even in three dimensions, it is impossible to change the posture of the weld seam and meet the welding requirements. That is to say, the displacement motion is a rotational motion, which is called the principal degree of freedom of the displacement machine. Another assumption can be made: in the X, Y, Z Cartesian coordinate system, there is a spatial straight line weld seam that can rotate around the Z axis within a range of 360 °, and this Z axis, together with this weld seam, can rotate around the X (or Y) axis within a range of ≥ 180 °. Therefore, the modified weld seam can be moved to the ship corner welding position for welding operations. In other words, a weld joint is composed of two collinear surfaces MN and an angle α. Within the above two rotation ranges, with appropriate rotation, the collinear surfaces MN can be made parallel to the horizontal plane, and the angles between these two surfaces and the horizontal plane are equal, each being α/2, which becomes the ship angle welding position. This assumption is that any complex welded component can meet the requirements of ship welding as long as it is installed on a welding positioner with a main degree of freedom of one full rotation and one half rotation. We refer to this dual rotary welding positioner as a fully functional positioner.

Variable degrees of freedom

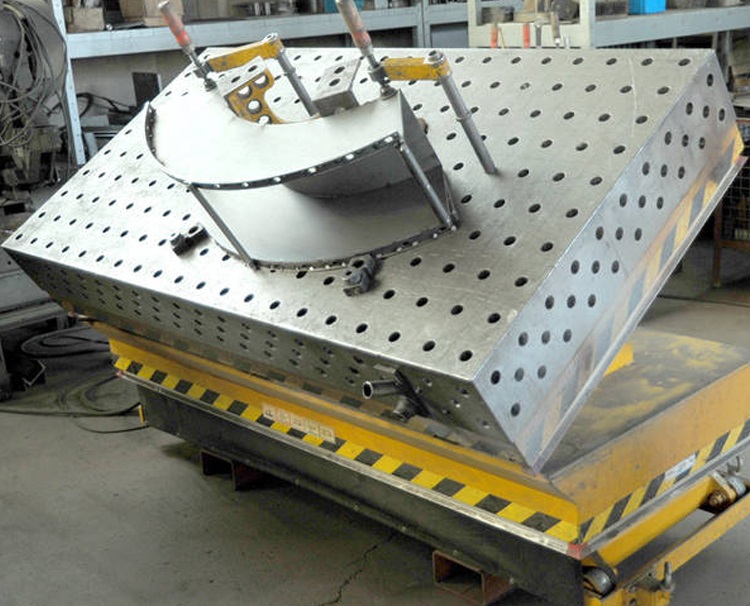

When it comes to the user's concept of equipment and considering the different uses for handle welding and automatic welding, when selecting and designing a welding positioner, in addition to the main variable degrees of freedom, it is also necessary to consider adding auxiliary variable degrees of freedom. If large items are welded, it can increase the freedom of lifting and lowering movements, as seen in many German products mentioned above.

In addition, for some welded components, due to the simple distribution of welds, most of the important welds in the welded components can be solved with one rotational degree of freedom for ship welding requirements. For the remaining small number of non important welds, although ship corner welding cannot be implemented, flat corner welding can be implemented. In this way, to simplify the equipment cost, it is considered to use a single degree of freedom or functionally degraded welding positioner, namely a single rotary positioner, in the process. According to usage requirements, auxiliary degrees of freedom can also be increased. For example, lift type and tailstock mobile type, etc.

There are also some workstation positioners that have certain degrees of freedom that are unrelated to welding, in order to meet the process requirements of welding workstations. From the perspective of workstation design and stability, two or more welding positioners are combined for design, resulting in various workstation transformations and combined multi degree of freedom welding positioners products.

Usage Editing

Main purpose: Welding positioner is a universal welding equipment mainly used for achieving circumferential seam welding. It can be equipped with argon arc welding machine (with or without wire filling), melting electrode gas shielded welding machine (CO2/MAG/MIG welding machine), plasma welding machine and other welding machine power supplies, and can be combined with other machines to form an automatic welding system. This product mainly consists of a rotating head, a displacement mechanism, and a controller. The rotating head speed is adjustable, with an independent speed control circuit, and the dip switch directly presets the weld seam length. The tilt angle can be adjusted as needed. The welding gun can be raised and lowered pneumatically.

Purpose:

Main purpose: Welding positioner is a universal welding equipment mainly used for achieving circumferential seam welding. It can be equipped with argon arc welding machine (with or without wire filling), melting electrode gas shielded welding machine (CO2/MAG/MIG welding machine), plasma welding machine and other welding machine power supplies, and can be combined with other machines to form an automatic welding system. This product mainly consists of a rotating head, a displacement mechanism, and a controller. The rotating head speed is adjustable, with an independent speed control circuit, and the dip switch directly presets the weld seam length. The tilt angle can be adjusted as needed. The welding gun can be raised and lowered pneumatically.

Key words:

Online Consultation