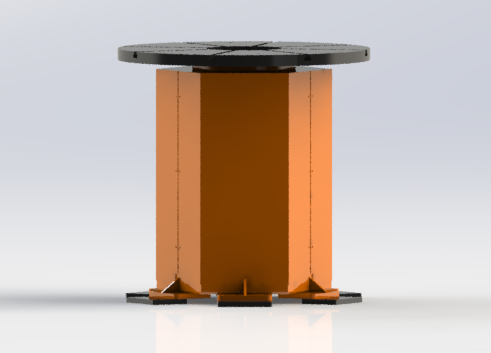

Three-axis welding positioner

- Commodity name:Three-axis welding positioner

- Manufacturer: Xinbao Intelligent

Product Details

Robot cantilever: a flexible arm that expands the boundaries of industrial automation

In today's industrial automation process, robotic cantilevers have become key equipment for improving production efficiency and optimizing workflows due to their unique design and excellent performance. It is like the agile arms of industrial robots, providing precise and efficient operational support for various complex tasks.

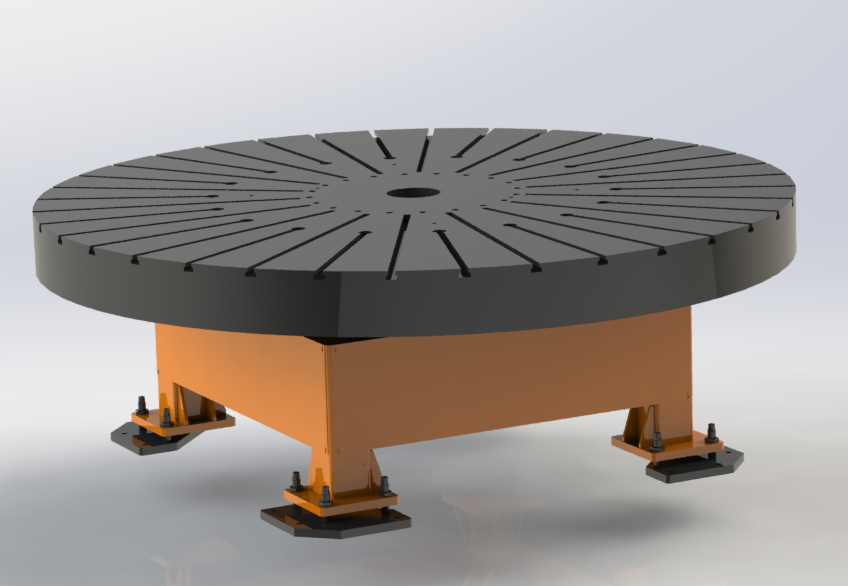

Three axis welding positioner: a precise assistant for welding process

In the field of welding, three-axis welding positioners provide efficient solutions for complex welding work with their excellent functionality and performance.

1、 Structural Design

Stable base and frame: The base of three-axis welded positioners is usually made of heavy metal materials, such as high-quality carbon steel or cast iron, to ensure sufficient stability and load-bearing capacity of the equipment during operation. The frame part has undergone precision machining and welding processes to ensure the overall structure is firm and reliable, effectively reducing vibration and shaking during the welding process.

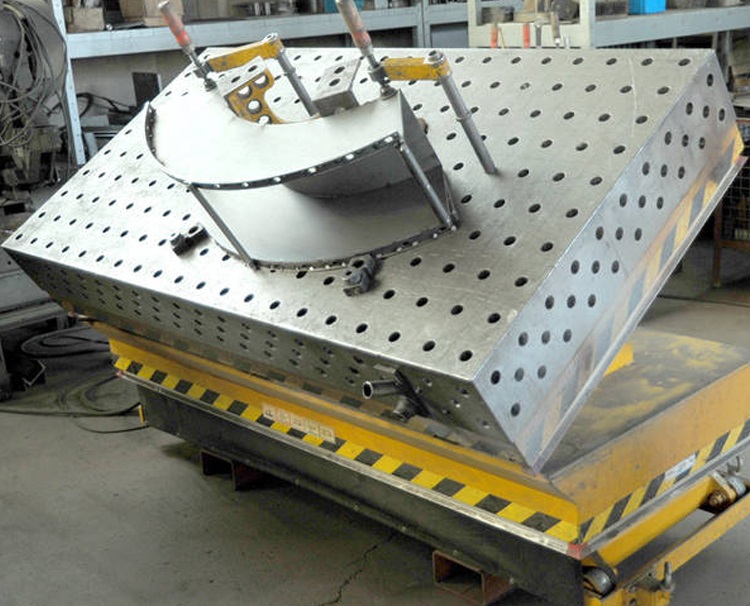

The composition of three motion axes: This positioner mainly includes three mutually perpendicular motion axes, namely the flipping axis, the rotating axis, and the tilting axis. Each shaft is equipped with high-precision transmission components such as bearings, gears, or worm gears, ensuring smooth and accurate motion. The flip axis can achieve a 180 ° or greater angle flip of the workpiece, the rotation axis can allow the workpiece to rotate continuously 360 °, and the tilt axis can adjust the tilt posture of the workpiece within a certain angle range. The collaborative work of these three axes provides comprehensive position adjustment for the workpiece.

2、 Performance characteristics

High precision positioning and repetitive positioning: Through advanced encoders and precise control systems, three-axis welding positioners can achieve high positioning accuracy, such as positioning accuracy up to ± 0.1 ° and repetitive positioning accuracy within ± 0.05 °. This enables the workpiece to accurately return to the preset position during the welding process, ensuring the accuracy of the weld position. For welding tasks with high requirements, such as pipeline welding, pressure vessel welding, etc., it can effectively reduce welding defects.

Flexible speed adjustment: Equipped with a speed control system, the speed of each motion axis can be flexibly adjusted according to the specific requirements of the welding process. For example, the rotational speed of the rotating shaft can be infinitely adjusted between 0.1-10 revolutions per minute. This flexible speed adjustment function helps to adapt to different welding speeds, making the weld more uniform and beautiful.

Powerful load capacity: The three-axis welding positioner has excellent load capacity and can carry workpieces of different weights. Depending on the model, its load-bearing capacity can range from several hundred kilograms to several tons, which can meet the welding needs of various sizes of workpieces. From small mechanical components to large steel structural components, they can be welded on it.

3、 Operational convenience

Intuitive operation interface: The device is equipped with a simple and clear operation panel, and operators can easily control the movement of the three motion axes through buttons, knobs, or touch screens, including start, stop, speed adjustment, angle setting, and other operations. Some high-end positioners can also be programmed to pre-set the motion trajectory of the workpiece during the welding process, achieving automated welding.

Compatibility with welding equipment: The three-axis welding positioner can be well compatible with various welding equipment, such as arc welding equipment, laser welding equipment, etc. It can automatically adjust the position of the workpiece based on the working signal of the welding equipment, so that the weld seam is always in the optimal welding position, improving welding efficiency and quality.

4、 Application Fields

Mechanical manufacturing industry: In the welding of mechanical parts such as gears, shafts, boxes, etc., three-axis welding positioners can adjust the parts to the appropriate welding position, facilitating welding workers or welding robots to weld various types of welds such as circular welds and butt welds, improving production efficiency and quality.

Pressure vessel and pipeline industry: For welding of cylinder and head of pressure vessels, welding of circumferential seams of pipelines, etc., this positioner can accurately control the position and angle of the workpiece, ensuring that the weld quality meets high standards, such as pressure testing standards, sealing standards, etc.

In the field of metal structure manufacturing: In the welding of large metal structures such as building steel structures and bridge steel structures, three-axis welding positioners can carry heavier steel components and flexibly adjust their positions, making welding work more efficient and accurate, thereby improving the quality and stability of the entire metal structure.

The three-axis welding positioner, with its reasonable structural design, excellent performance characteristics, convenient operation mode, and wide application fields, has become an important equipment for improving welding quality and efficiency in the welding industry, providing strong support for the refinement and automation of welding processes.

Key words:

Online Consultation