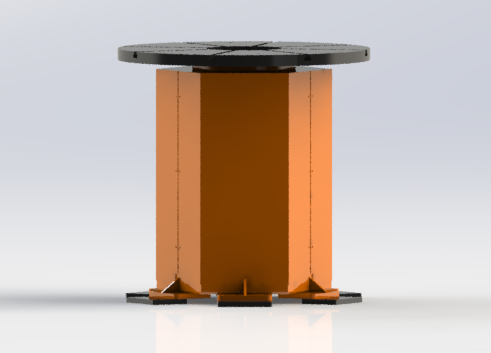

轴类激光熔覆变位机

- Commodity name:轴类激光熔覆变位机

- Manufacturer: Xinbao Intelligent

Product Details

Introduction to axis laser cladding positioner:

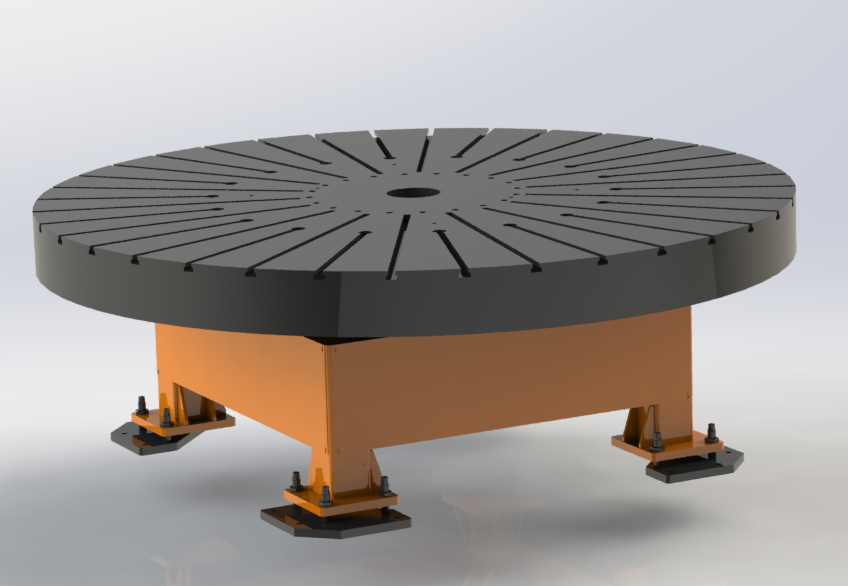

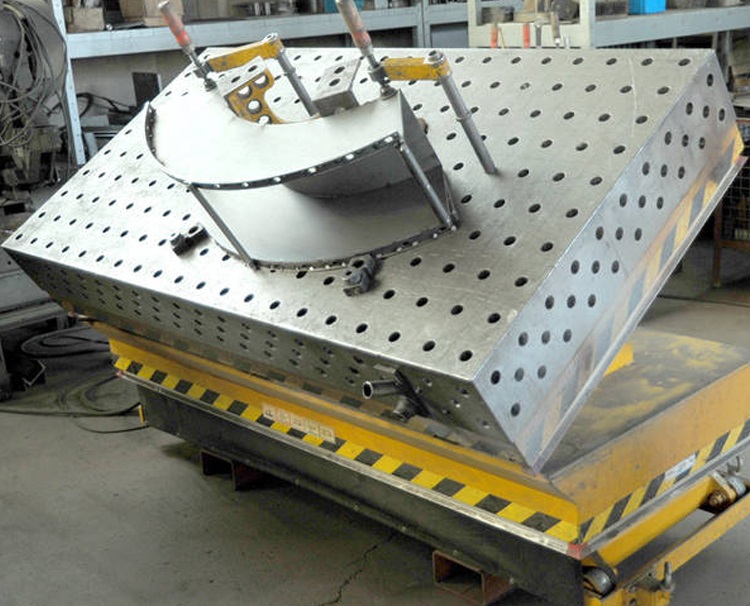

Structural composition

-Rotating spindle box: usually equipped with a chuck, such as a three jaw self centering chuck, used to clamp shaft workpieces, drive them to rotate around the axis, and achieve laser cladding processing in the circumferential direction of shaft workpieces.

-Hydraulic tailstock: It can slide and lock on the base, and its extension and contraction are driven by hydraulic pressure. The stroke is generally designed according to actual needs, such as 80mm. The tailstock is equipped with a pressure detection and display device, and is equipped with a movable top to ensure a constant pushing force on the shaft workpiece during the melting process.

-Adjustable idler: Used as an auxiliary support for long axis workpieces to prevent deformation or vibration caused by their own weight during rotation. It can slide and lock on the base according to the diameter of the workpiece, and generally one set of displacement machine is equipped with two sets of rollers.

-Basic welding base: As the supporting foundation of the entire equipment, it is usually welded with high-strength steel, which has high strength and stability, and can withstand the weight of shaft workpieces and other components.

-Control system: used to control the speed of the spindle motor, the action of the hydraulic tailstock, etc., to achieve precise operation and control of the positioner, in order to meet the process requirements of laser cladding processing for different types of shaft workpieces.

working principle

The axis laser cladding positioner adjusts the speed of the rotating spindle box through the control system to rotate the axis workpiece at an appropriate speed. At the same time, it cooperates with the laser head of the laser cladding equipment to evenly irradiate the surface of the axis workpiece, achieving laser cladding processing of the circumference or other parts of the axis workpiece. During the processing, the hydraulic tailstock and adjustable idler ensure the stability and coaxiality of the shaft workpiece during rotation.

technical parameter

-Spindle speed: Generally adjustable within the range of 0-100r/min, the spindle speed of different load-bearing capacity positioners varies. For example, the spindle speed of positioners below 1T can reach 100rpm, while those above 1T are generally 30rpm.

-Positioning accuracy: The positioning accuracy of the chuck is generally ± 5arcmin, and the positioning accuracy of the tailstock tip is ≤ 0.15mm/full length. The coaxiality between the spindle chuck and the tailstock tip is ≤ 0.15 within the full length range.

-Load capacity: Depending on different models and designs, the load capacity ranges from several hundred kilograms to tens of tons, which can meet the laser cladding processing needs of workpieces of different sizes and weights.

application area

-Automotive manufacturing: used for surface strengthening and repair of shaft components such as crankshafts and camshafts in automotive engines, improving the wear and corrosion resistance of the parts and extending their service life.

-Aerospace: It can repair and strengthen key components such as aircraft engine blades and turbine shafts, improve component performance and reliability, and ensure the safe operation of aerospace equipment.

-Energy and Electricity: Suitable for the manufacturing and repair of shaft components of energy equipment such as generator shafts and turbine shafts, enhancing the wear resistance, corrosion resistance, and fatigue resistance of components, and improving the operational efficiency and stability of energy equipment.

-Mechanical processing: repairing surface wear, scratches, and other issues of various mechanical shaft components such as transmission shafts and lead screws, as well as surface strengthening treatment of newly manufactured shaft components to improve their quality and performance.

Key words:

Online Consultation