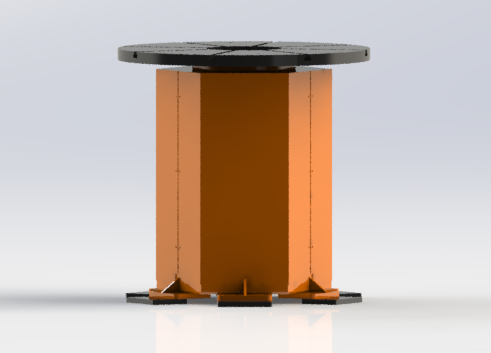

私服驱动p型双轴变位机

- Commodity name:私服驱动p型双轴变位机

- Manufacturer: Xinbao Intelligent

Product Details

Servo driven dual axis P-type welding positioner: the core equipment for revolutionizing welding processes

In the field of modern welding manufacturing, the requirements for welding quality, efficiency, and workpiece adaptability are becoming increasingly stringent. As an advanced equipment leading the industry revolution, the servo driven dual axis P-type welding positioner provides efficient and accurate solutions for various complex welding tasks with its outstanding performance.

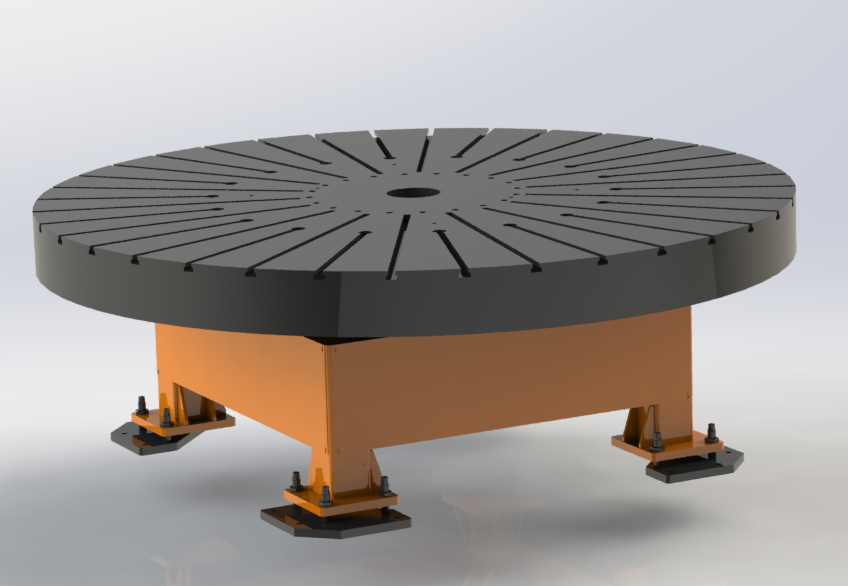

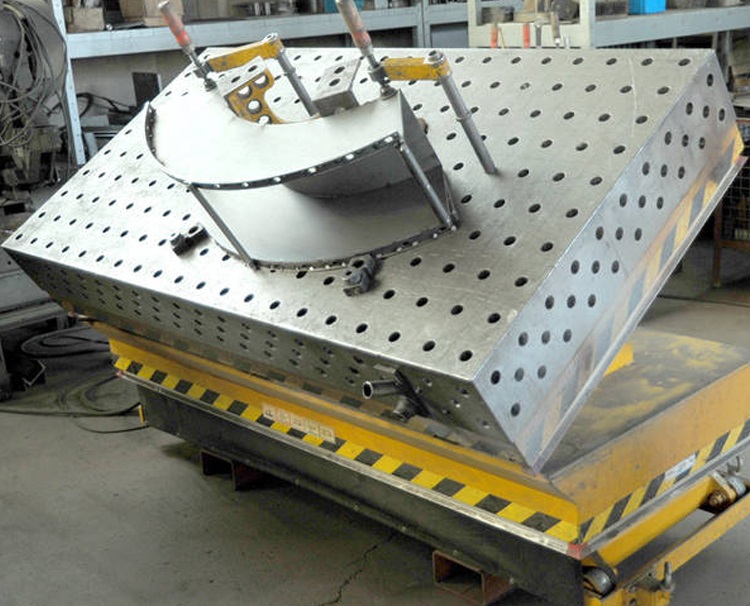

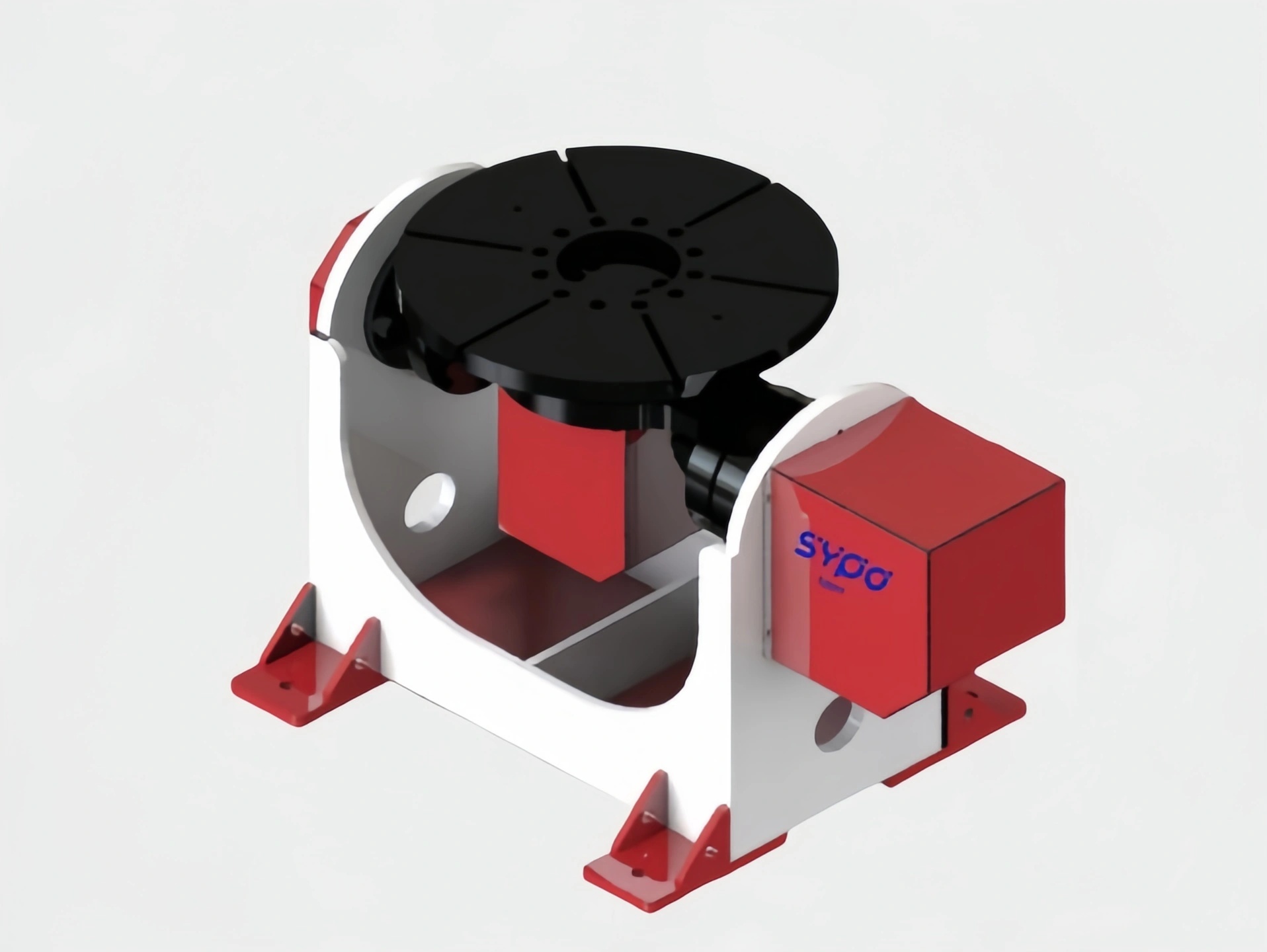

The unique "P" - shaped architecture enables the dual axis to provide a wider range of motion space and flexible posture adjustment range for the workpiece during collaborative operation. Whether it is multi angle welding of large structural components or precise operation of small precision parts, it can be easily handled, greatly expanding the application boundaries of welding technology.

Dual axis precision linkage: equipped with two high-precision servo drive axes, responsible for rotation and tilt actions respectively. The precise linkage between the two axes is achieved through an advanced control system, which can complete various complex trajectory movements according to preset programs. This precise collaborative operation ensures that the workpiece is always in the optimal welding position during the welding process, effectively reducing weld deviation and improving the stability and consistency of welding quality.

Servo drive, leading efficient and precise welding

High response speed and precise positioning: Equipped with high-performance servo motors, the dual axis P-type welding positioner has excellent response speed. From start-up to reaching the set speed, it only takes a very short time and can quickly respond to the dynamic requirements of the welding process. At the same time, the high-precision encoder of the servo system can provide real-time feedback on the position information of the axis, achieving a positioning accuracy of ± [X] mm, and the repeated positioning accuracy is controlled within a very small error range, providing a solid guarantee for high-quality welding.

Stable torque output: Under different load conditions, servo motors can provide stable and powerful torque output. This means that even when facing large workpieces weighing up to [X] kilograms, the positioner can be easily driven to ensure smooth operation during rotation and tilting, without lagging or shaking due to load changes, effectively improving the smoothness and reliability of the welding process.

Easy to operate, improving production efficiency

Humanized operation interface: equipped with an intuitive and easy to understand operation panel, operators can easily complete various parameter settings such as rotation speed, tilt angle, motion mode, etc. through simple buttons and clear display screens. In addition, it also supports teaching function. Operators only need to manually drag the positioner to the desired position, and the equipment can automatically record the action trajectory and repeat it in subsequent production, greatly reducing the difficulty of operation and programming workload.

Flexible communication interface: With rich communication interfaces, it can seamlessly connect with various welding power sources, robot control systems, and factory automation networks. Fully automated control of the welding process has been achieved, resulting in smoother data exchange and collaborative operations between different devices, greatly improving production efficiency and reducing labor costs.

Widely used to meet the diverse needs of various industries

With its excellent performance and high adaptability, servo driven dual axis P-type welding positioners have been widely used in many industries. In the field of shipbuilding, it is used for welding large ship structural components to improve welding quality and production efficiency, and shorten the shipbuilding cycle; In the pressure vessel manufacturing industry, ensuring high-precision positioning during the welding of the vessel cylinder and head ensures the safety and reliability of the product; In the field of automobile manufacturing, we assist in the welding production of key components such as automobile chassis and body, improving the overall performance and quality of automobiles.

The servo driven dual axis P-type welding positioner has become an indispensable key equipment in modern welding manufacturing processes due to its innovative design, advanced driving technology, convenient operation, and wide applicability. It not only brings higher production efficiency and better product quality to enterprises, but also injects strong impetus into the technological upgrading and development of the entire welding industry.

Key words:

Online Consultation