Robot Seventh Axis

- Commodity name:Robot Seventh Axis

- Manufacturer: Xinbao Intelligent

Product Details

Robot Seventh Axis Product Introduction:

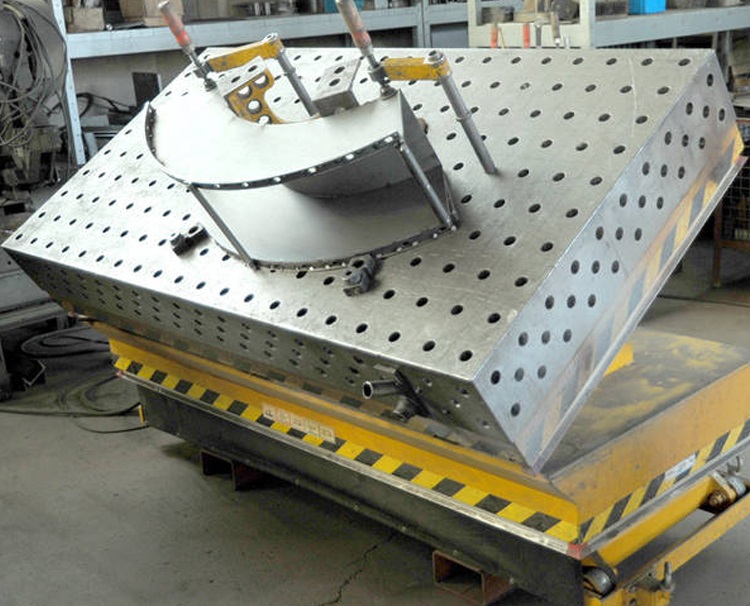

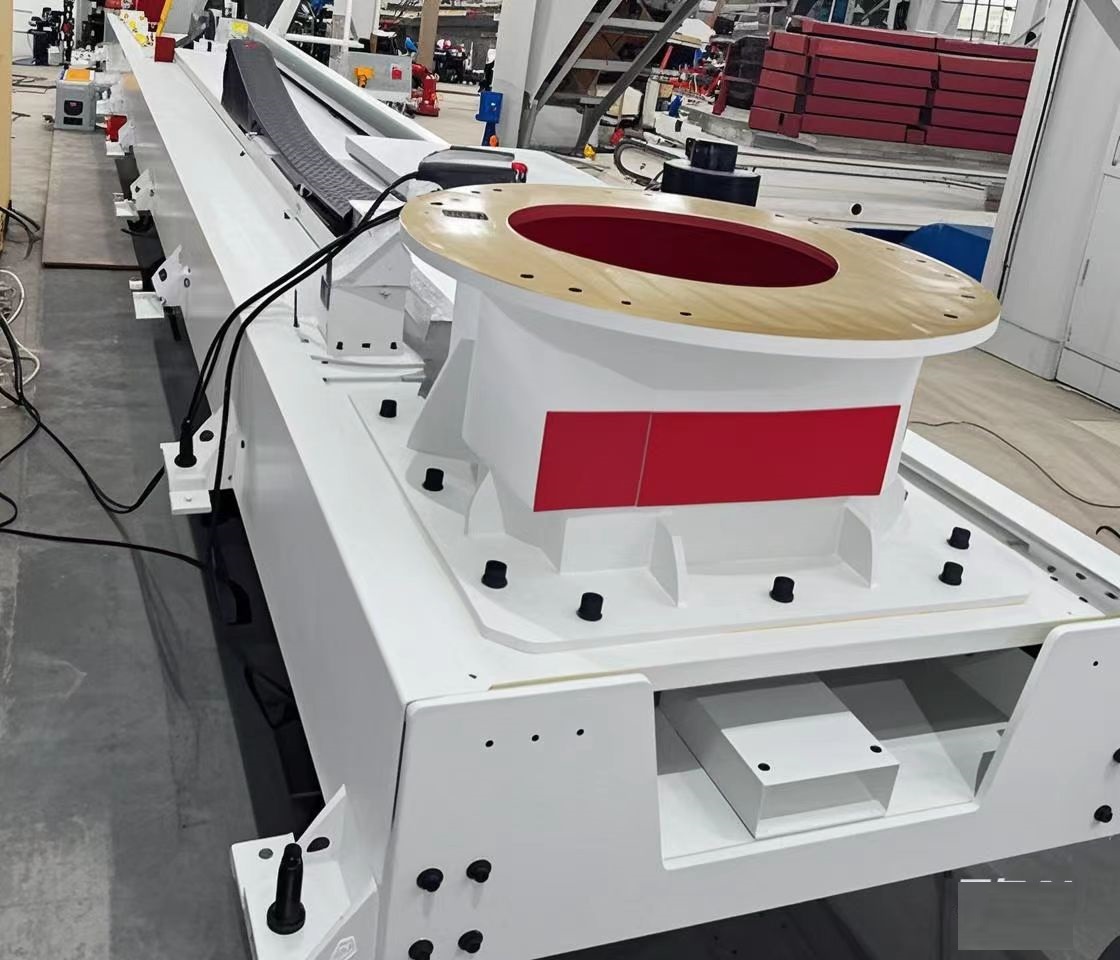

The seventh axis walking axis of a robot, also known as the robot's seventh axis, robot track, etc., is mainly used to expand the robot's operating radius, expand the robot's range of functions, and is mainly applied in industries such as welding, casting, mechanical processing, intelligent warehousing, automotive, aerospace, etc.

We are committed to providing excellent walking axis solutions for every robot through continuous technological advancement. Provide good load-bearing platforms, reducers, and drag chains for each robot.

At present, welding track bases are basically used both domestically and internationally. In fact, in Germany and Japan, many machine tools also use welding bed bodies, which is closely related to their related technologies. In China, many large machine tool manufacturers have tried to use welding bed bodies, but they have basically failed. Firstly, there is no accuracy, and secondly, there is significant deformation during use, which is basically difficult to adjust. In other words, there is a significant gap between domestic materials, welding processes and equipment, mechanical processing processes and equipment and Germany and Japan. Therefore, the effective stroke of the seventh axis of robots is relatively long, and it is currently difficult to achieve precision and service life in China. So using a cast base, the performance of the cast base is obviously much better than that of the welded base, with significant advantages in accuracy, deformation, and vibration absorption.

The newly developed robot walking system adopts API laser interferometer to measure its walking positioning accuracy, straightness, repeat positioning accuracy, etc., and issue a qualified measurement report for each product.

The main technical parameters of the seventh axis system of the robot are as follows:

Load capacity 2 tons

Effective travel distance of 50m

Repetitive positioning accuracy ± 0.05mm

The straightness of the guide rail is 0.3mm/12m

Mobile speed 0~30m/min (adjustable)

Intermittent operation mode

Mobile acceleration 2m/s2

Total number of workstations 8 (quantity to be specified by the customer)

Drive motor 40Nm

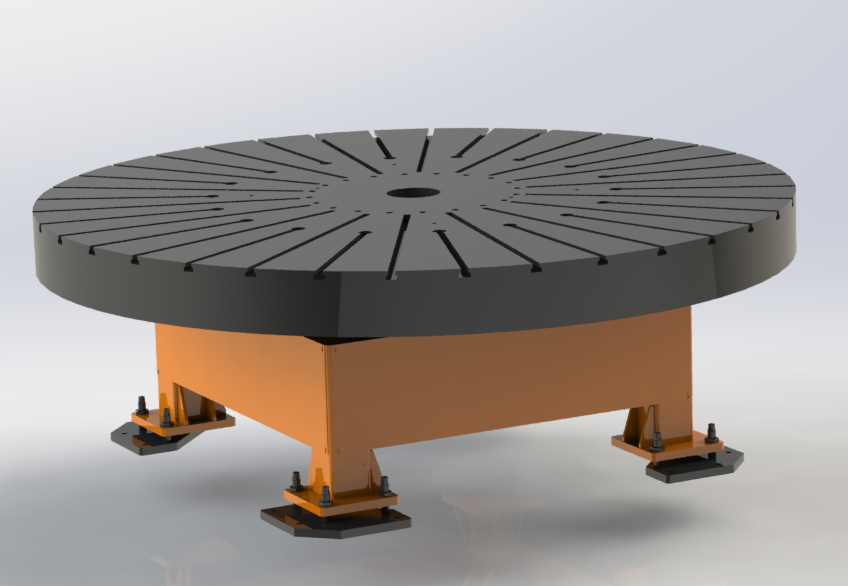

Casting base width 500mm

Workbench width 550mm

The seventh axis system of the robot mainly includes:

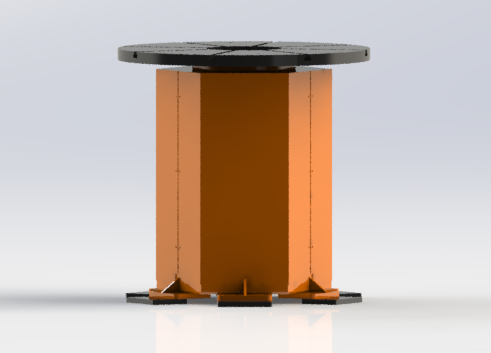

1. Casting base

2. Imported heavy-duty linear guide rail

3. Imported high-precision large modulus grinding high-precision gear rack

4. Imported servo system and planetary gearbox

5. Sustainable self lubrication system that provides lubrication

6. Dust prevention system (fully enclosed style)

7. Travel switch

8. Buffer device

9. High flexibility silent drag chain

Key words:

Online Consultation