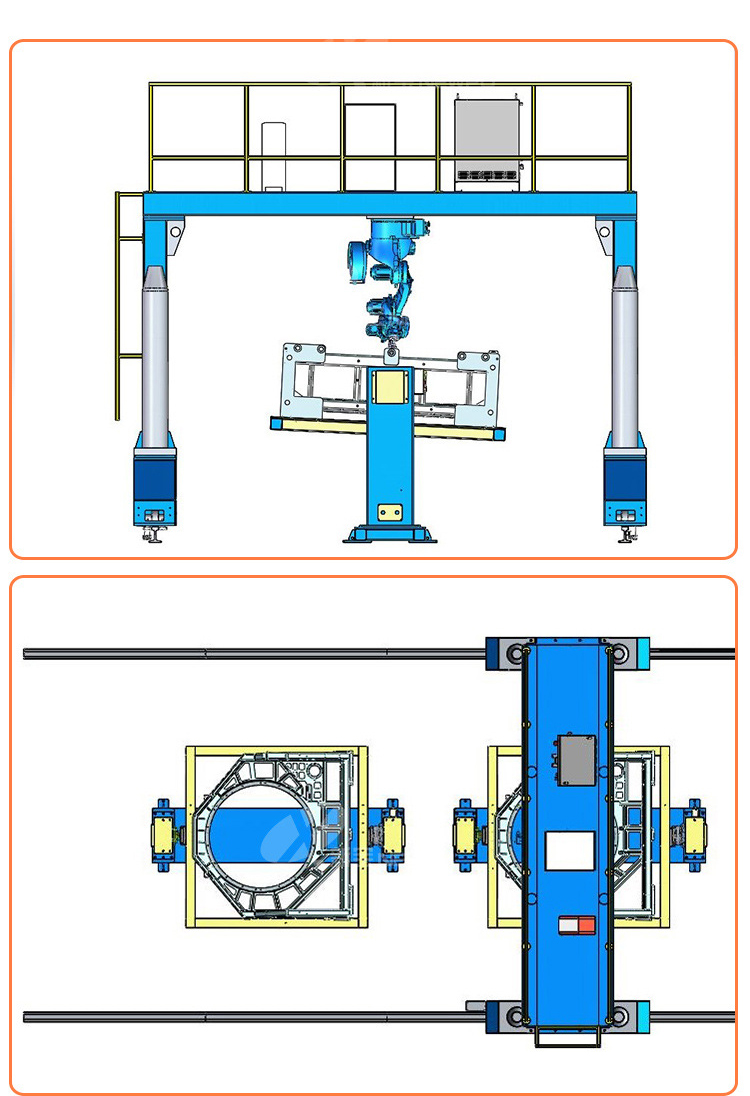

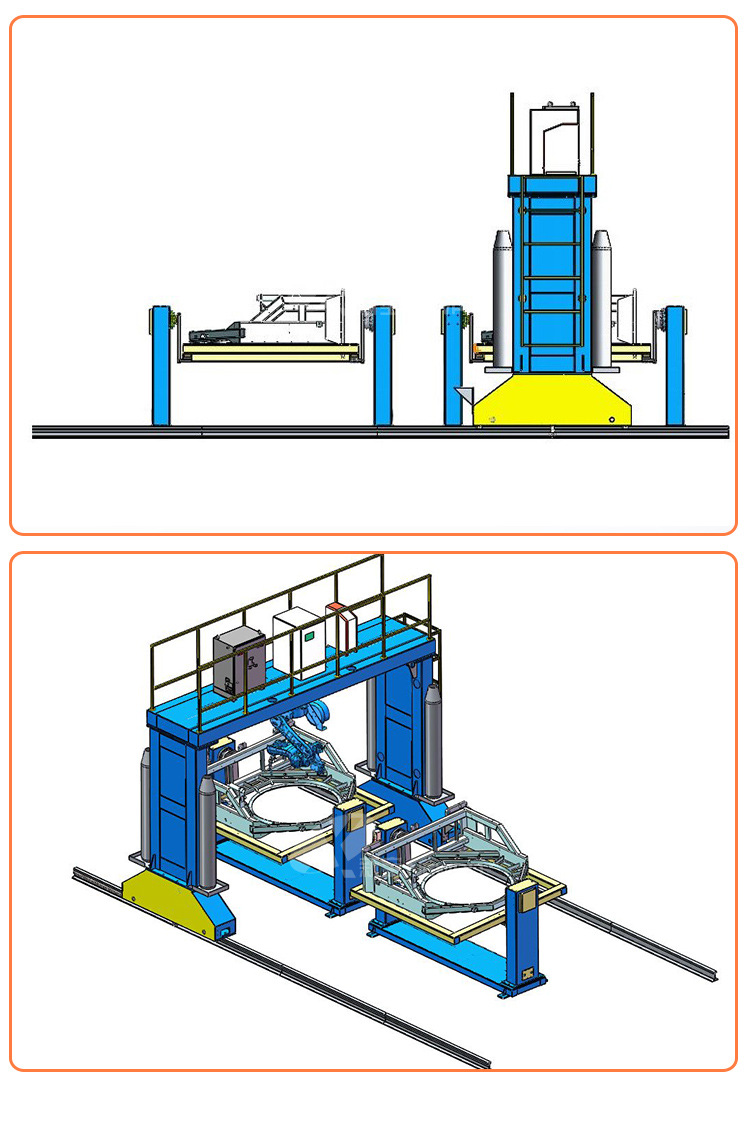

Robot gantry crane arm

- Commodity name:Robot gantry crane arm

- Manufacturer: Xinbao Intelligent

Product Details

Design principles for welding workstations:

Due to the fact that the design of welding workstations is a flexible and variable technical task with many interrelated factors, we can only abstract common factors and derive some general design principles.

(1) Before design, it is necessary to fully analyze the work object and formulate a more reasonable work process;

(2) Must meet the functional requirements and environmental conditions of the assignment;

(3) Must meet the production cycle requirements;

(4) The whole and all its components must meet safety regulations and standards;

(5) Each equipment and control system should have fault display and alarm devices;

(6) Easy to maintain and repair;

(7) The operating system is convenient for networked control;

(8) Workstations are convenient for cable assembly;

(9) The operating system should be simple and clear, easy to operate and manually intervene;

(10) Economical and fast production.

These 10 design principles collectively reflect the diverse needs of workstation users, simply put, they strive to meet their requirements in every possible way.

Design steps of welding workstation:

1. Planning and system design

Planning and system design include task division within the design unit, robot inspection and inquiry, preparation of planning forms, operation system design, detailed planning of external equipment (auxiliary equipment, supporting equipment, safety installation, etc.) capabilities, and resolution of key issues.

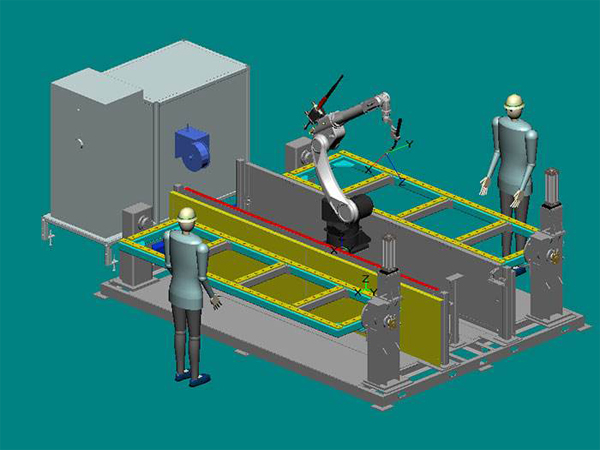

2. Layout design

Layout design includes robot selection, human-machine system configuration, logistics routes for work objects, wiring of electrical, hydraulic, and gas systems, positioning of operation boxes and electrical cabinets, as well as maintenance, repair, and safety facility configuration.

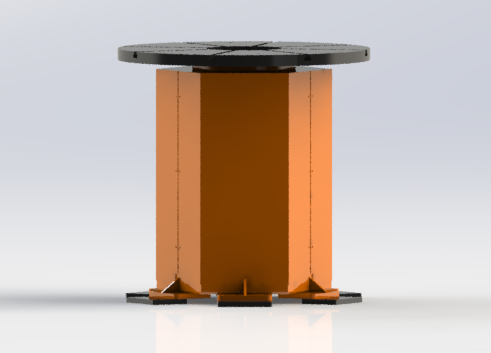

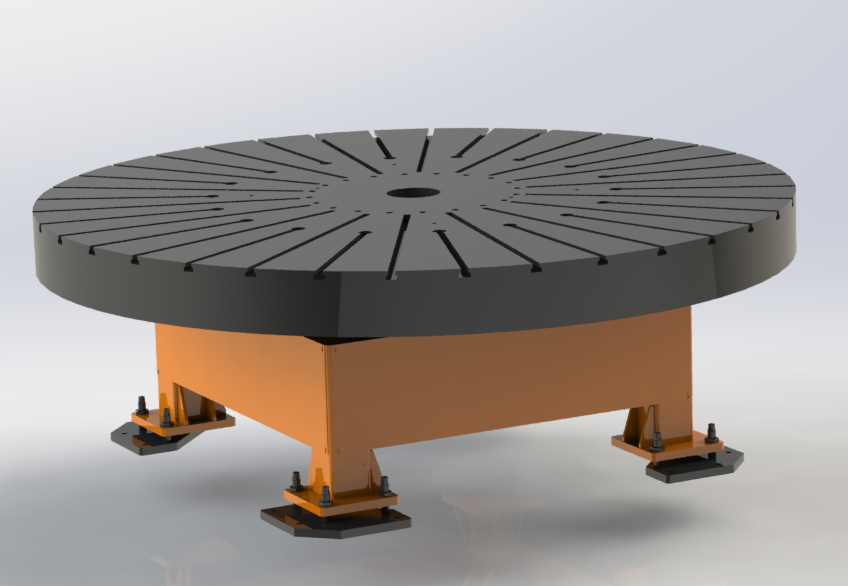

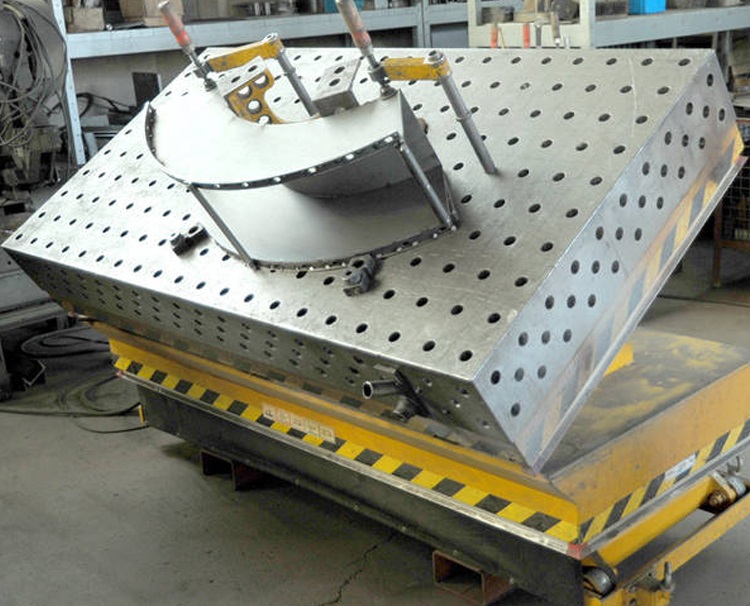

3. Expand the application scope of robots and select and design auxiliary equipment

The tasks of this job include the use of end effectors for robots to complete tasks, fixtures and positioners for fixing and changing the pose of the work object, and the selection and calculation of machine bases for changing the direction and scope of robot actions. Generally speaking, this part requires a significant amount of design work.

4. Selection and design of supporting and safety devices

This work mainly includes the selection and design of supporting equipment (such as wire cutting and welding gun cleaning equipment for arc welding) required by the work and the world; The selection and design of safety devices (such as fences, safety gates, etc.) and the modification of existing equipment.

5. Control system design

This design includes the standard control types and additional performance of the selected system. Determine the sequence and methods of system operation, as well as safety design such as interlocking; Testing of hydraulic, pneumatic, electrical, electronic equipment and backup equipment; Electrical control circuit design; The design of robot circuits and the entire system circuit, etc.

6. Support system

This task is to design a support system that should include fault queuing and repair methods, countermeasures and preparations during downtime, preparation for backup machines, and emergency measures in case of unexpected situations.

7. Engineering construction design

This design includes writing instructions for the working system, detailed performance and specification manuals for the robot, receiving inspection texts, standard part manuals, drawing engineering drawings, and compiling drawing lists.

8. Prepare procurement documents

This task includes writing a robot valuation commission, robot performance and self inspection results, compiling a standard parts procurement list, training operator plans, maintenance instructions, and various budget plans.

Key words:

Online Consultation