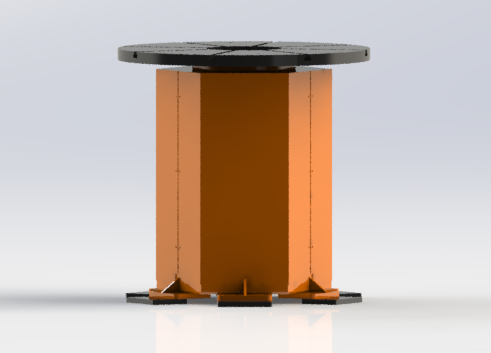

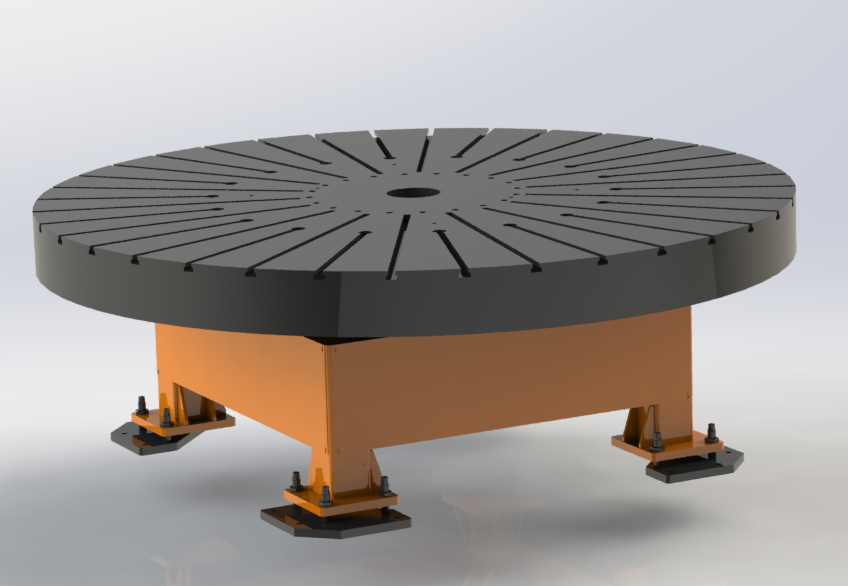

Industrial manipulator

- Commodity name:Industrial manipulator

- Manufacturer: Xinbao Intelligent

Product Details

Characteristics of industrial robotic arms:

Industrial robotic arms meet the needs of social production and bring economic benefits. Its characteristics include:

① Strong adaptability to the environment, able to replace humans in dangerous and harmful operations. In places where long-term work is harmful to the human body, the robotic arm is not affected. As long as reasonable calculations are made according to the workpiece environment, appropriate materials and structures are selected, the robotic arm can work under abnormal high or low temperatures, abnormal pressures, harmful gases, dust, and radiation.

② Mechanical arms are long-lasting and durable, capable of freeing people from heavy and monotonous labor, and expanding and extending their functions. As long as the maintenance and repair of the robotic arm are paid attention to, it can be competent for long-term monotonous and repetitive labor.

③ Accurate movements can ensure and improve product quality, while avoiding human operational errors.

④ Good universality and flexibility, especially for general industrial robotic arms, which can adapt to the rapidly changing requirements of product varieties and meet the needs of flexible production. This is because the action program and motion position (or trajectory) of the robotic arm can be flexibly changed, with numerous degrees of freedom, and can quickly change the job content to meet production requirements. As a medium to small batch production automation, it can better play its role.

⑤ The use of robotic arms can significantly improve labor productivity and reduce costs.

Classification of industrial robotic arms:

1. Classified by usage scope

(1) A specialized robotic arm is a mechanical device that is attached to the host and has a fixed (sometimes adjustable) program to control the system. Specialized robotic arms have the characteristics of few movements, single working objects, simple structure, and reliable operation, making them suitable for large-scale automated production. Currently widely used in the light industry and electronics industry.

(2) A universal robotic arm is a type of robotic arm with an independent control system, variable programs, and flexible and diverse actions. Universal robotic arms have a wide working range, high positioning accuracy, and strong versatility, making them suitable for small and medium-sized automated production that constantly changes production varieties. They are widely used in flexible automatic production lines.

2. Divided by driving mode

(1) Mechanical transmission manipulator is a manipulator driven by a mechanical transmission mechanism (cam, connecting rod, gear, rack, etc.) to move the actuator. Its main features are accurate and reliable movement, high frequency of movements, but with a large structural size and an immutable movement program. Generally used as a loading or unloading device for automatic machines.

(2) Hydraulic transmission robotic arm is a mechanical arm that drives the movement of the actuator with the pressure of oil. Strong grasping ability, compact and lightweight structure, smooth transmission, agile movement, stepless speed regulation, and continuous trajectory control. However, due to the significant impact of oil leakage on work performance, it has strict requirements for sealing devices and should not work at high or low temperatures.

(3) Pneumatic transmission manipulator is a mechanical arm that uses the pressure of compressed air to drive the movement of the actuator. Its main characteristics are convenient medium source, rapid pneumatic action, simple structure, low cost, and the ability to work in environments with high temperature, high speed, and large dust. However, due to the compressibility of air, the stability of working speed is poor, and due to the low pressure of the air source, it is only suitable to work under light loads.

(4) Electric transmission manipulator is a manipulator that is directly driven by a specially designed electric motor, linear motor, or stepper motor to move the actuator. Due to the absence of intermediate conversion mechanisms, the structure is simple, and the linear motor manipulator has fast movement speed, long stroke, and easy use and maintenance. At present, mechanical design is developing towards the direction of "mechatronics integration", and the use of electric direct drive mechanical arms will increasingly increase.

Application of industrial robotic arms:

The application of industrial robotic arms in industrial production is extremely extensive, mainly in the following aspects:

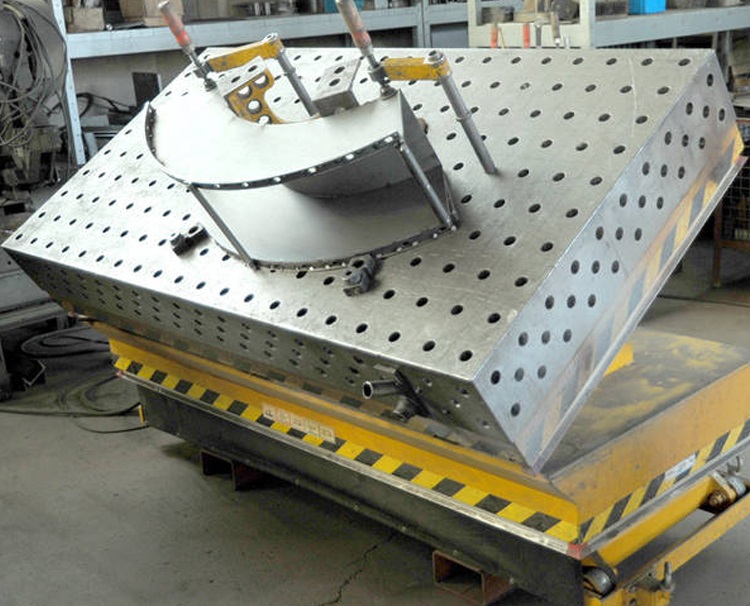

① Realize single machine automation: automatic loading and unloading of various semi-automatic machine tools.

② Forming an automatic production line: On the basis of single machine automation, automatic loading and unloading and conveying of workpieces can connect some single machines into an automatic production line.

③ Special working environments: such as high temperatures (heat treatment, forging, casting, etc.), toxic and harmful environments, interstellar exploration, underwater resource development, etc. Mechanical arms (or automatic or remote control) are used to replace humans for operations.

Key words:

Online Consultation