Arc welding robot

- Commodity name:Arc welding robot

- Manufacturer: Xinbao Intelligent

Product Details

The system composition of arc welding robot:

The general arc welding robot consists of a teaching box, control panel, robot body, automatic wire feeding device, welding power supply, and other parts. Continuous trajectory control and point position control can be achieved under the control of a computer. Linear interpolation and arc interpolation functions can also be used to weld spatial welds composed of straight lines and arcs. Arc welding robots are mainly divided into two types: melting electrode welding operations and non melting electrode welding operations. They have the characteristics of being able to perform welding operations for a long time, ensuring high productivity, high quality, and high stability of welding operations. With the development of technology, arc welding machines are moving towards intelligence.

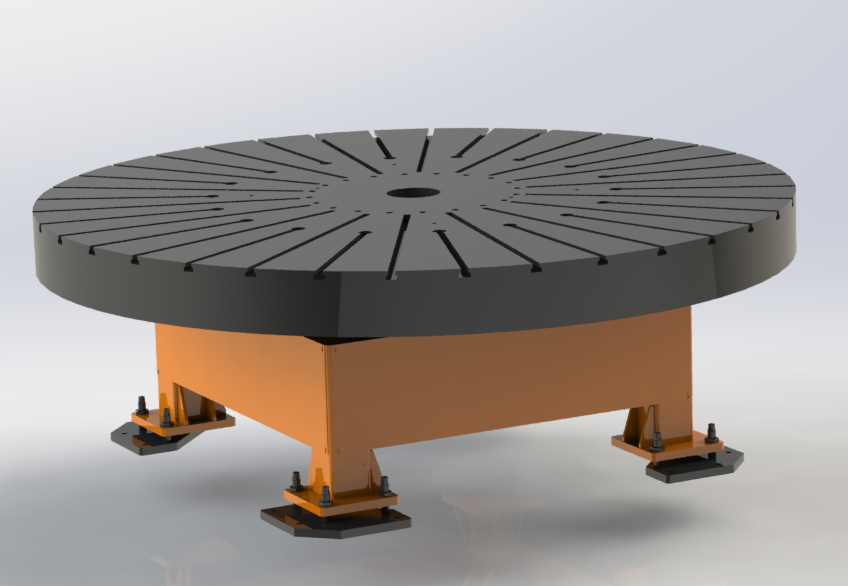

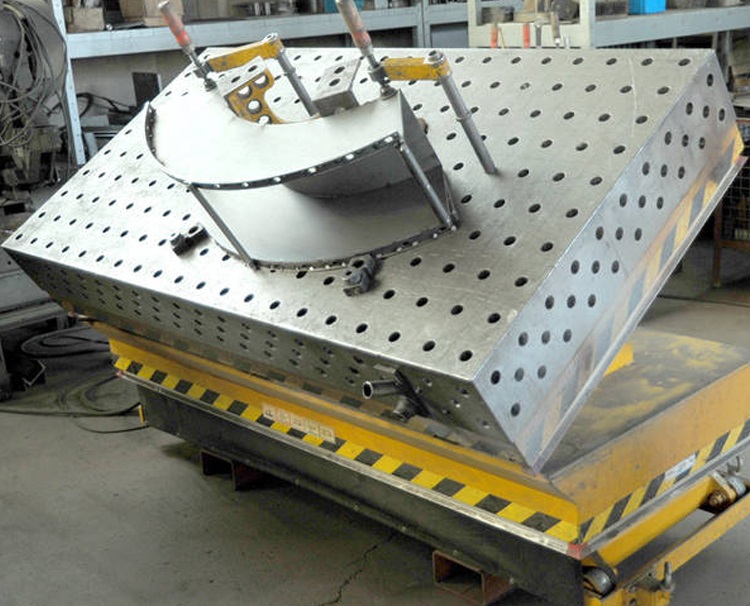

The basic components of the arc welding robot system are as follows: robot body, control system, teaching pendant, welding power source, welding gun, welding fixture, and safety protection facilities.

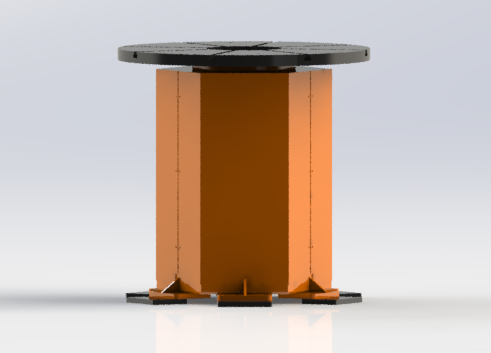

The system composition can also be selectively expanded according to different welding methods and specific welding process requirements of the workpiece to be welded, including wire feeders, gun cleaning and wire cutting devices, cooling water tanks, flux conveying and recovery devices (SAW), mobile devices, welding positioners, sensing devices, dust removal devices, etc.

Characteristics of arc welding robots:

(1) Stabilize and improve welding quality to ensure uniformity. When using robot welding, the welding parameters for each weld seam are constant, and the quality of the weld seam is less affected by human factors, reducing the requirements for worker operation skills. Therefore, the welding quality is stable. However, during manual welding, welding speed, dry elongation, and other factors vary, making it difficult to achieve uniformity in quality.

(2) Improved the working conditions of workers. The use of robot welding workers is only for loading and unloading workpieces, away from welding arc light, smoke and private splashes.

(3) Improve labor productivity. Robots have no fatigue and can produce continuously for 24 hours a day. In addition, with the application of high-speed and efficient welding technology, the use of robots for welding has significantly improved efficiency.

(4) Clear product cycle makes it easy to control product output. The production cycle of robots is fixed, so the production plan is very clear.

(5) It can shorten the product replacement cycle and reduce the corresponding equipment investment. It can achieve welding automation for small batch products. The major difference between robots and specialized machines is that they can adapt to the production of different workpieces by modifying the program.

Key technologies of arc welding robots:

(1) Optimization and integration technology for arc welding robot system: The arc welding robot adopts AC servo drive technology and high-precision, high rigidity RV reducer and harmonic reducer, which have good low-speed stability and high-speed dynamic response, and can achieve maintenance free function.

(2) Coordination control technology: Control the coordinated movement of multiple robots and positioners, which can maintain the relative posture between the welding gun and the workpiece to meet the requirements of the welding process, while avoiding collisions between the welding gun and the workpiece.

(3) Accurate weld seam trajectory tracking technology: Combining the advantages of offline working methods of laser sensors and visual sensors, laser sensors are used to achieve weld seam tracking during the welding process, improving the flexibility and adaptability of welding robots to complex workpieces. Combined with offline observation of visual sensors, residual deviations in weld seam tracking are obtained. Based on deviation statistics, compensation data is obtained and the robot's motion trajectory is corrected, achieving better welding quality under various working conditions.

Key words:

Online Consultation