行走式变位机

- Commodity name:行走式变位机

- Manufacturer: Xinbao Intelligent

Product Details

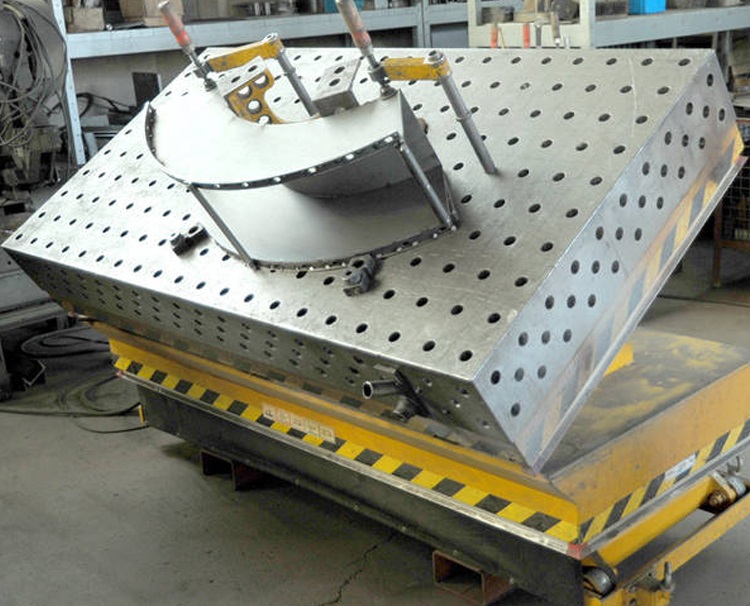

The walking positioner is a widely used equipment in industrial production, mainly used to change the position and posture of workpieces to meet different processing requirements, such as welding, cutting, polishing, laser cladding, etc. Its unique "one head fixed and one head walking" structural design gives it significant advantages in processing large and large-sized workpieces, effectively improving processing efficiency and quality.

Structural characteristics

Fixed end:

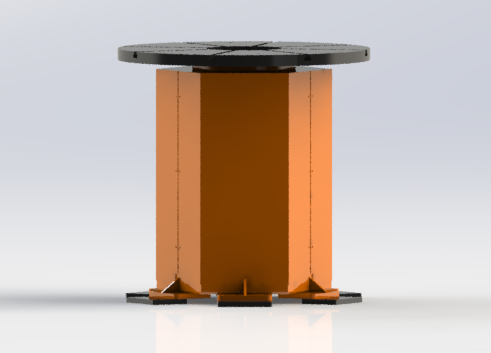

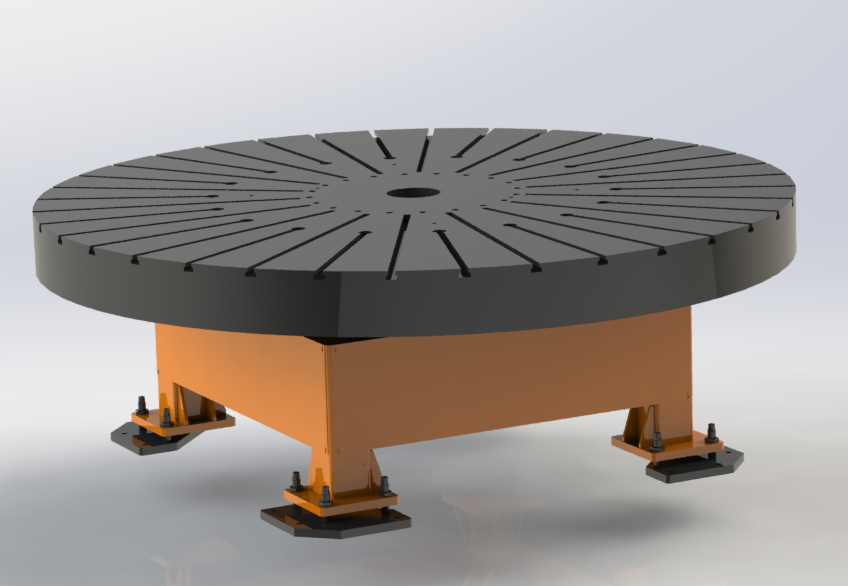

-The fixed end usually consists of a sturdy base and a spindle box mounted on it. The base is made of high-strength cast iron or welded steel structure, which has good stability and seismic resistance, and can withstand the weight of the workpiece and various forces generated during the processing.

-The spindle box is equipped with high-precision rotary bearings and drive motors, which can achieve precise rotation of the workpiece. The accuracy and load-bearing capacity of rotary bearings directly affect the rotational accuracy and stability of workpieces, and high-grade cross roller bearings or four point contact ball bearings are generally selected. AC servo motors are commonly used as driving motors, which are connected to the spindle through precision reducers, providing stable torque output and precise control of rotation speed and angle.

Walking end:

-The walking end mainly includes the walking trolley, guide rail, and drive system. The walking trolley is connected to the spindle box at the fixed end through a connecting shaft or other connecting components, used to support the other end of the workpiece. The trolley is made of high-quality steel and undergoes strict processing and heat treatment processes to ensure its strength and rigidity.

-The guide rail is generally installed on the workshop floor, using high-precision linear guide rails or heavy-duty steel rails. Linear guides have the advantages of high motion accuracy and low friction, which can ensure the smooth and steady movement of the walking trolley; Heavy duty steel rails are suitable for carrying heavy workpieces, with high load-bearing capacity and wear resistance.

-The walking drive system usually adopts motor drive, which drives the walking trolley to move on the guide rail through transmission devices such as reducer, chain or gear rack. The motor also uses AC servo motor or variable frequency motor to achieve precise speed control and positioning. During the walking process, real-time position information is fed back through position sensors installed on the trolley (such as encoders or grating rulers), and the control system adjusts the walking speed and position accurately according to the preset program.

Wide processing range: Due to the use of a fixed head and walking head structure design, the walking positioner can adapt to the processing needs of workpieces of different lengths and weights. Whether it is a small workpiece of short size or a large workpiece of tens of meters in length, it can be processed by adjusting the position of the walking end and the rotation parameters of the fixed end.

High processing accuracy: Both the fixed end and the walking end of the walking positioner are equipped with high-precision transmission devices and positioning systems, which can achieve precise rotation and movement of the workpiece. With advanced control systems, the position and orientation of the workpiece can be controlled within a very small error range, meeting the requirements of high-precision machining.

Improving production efficiency: By using a walking positioner, the processing equipment can continuously process different parts of the workpiece, reducing the number of clamping times and adjustment time, greatly improving production efficiency. Meanwhile, due to the ability to achieve automated control, operators only need to perform simple parameter settings and monitoring, reducing labor intensity and improving production stability and consistency.

Strong flexibility: The control system of the walking positioner has good programming functions and scalability, and can be flexibly programmed according to different processing requirements. Operators can set multiple processing paths and parameters according to actual needs to achieve processing of workpieces of different shapes and sizes, with strong adaptability and flexibility.

In summary, as an important industrial processing auxiliary equipment, the walking positioner plays an increasingly important role in modern manufacturing with its unique structural design, high-precision control performance, and wide application fields. It has made significant contributions to improving product quality, reducing production costs, and promoting the automation and intelligent development of industrial production.

Key words:

Online Consultation