Non teaching welding robot

- Commodity name:Non teaching welding robot

- Manufacturer: Xinbao Intelligent

Product Details

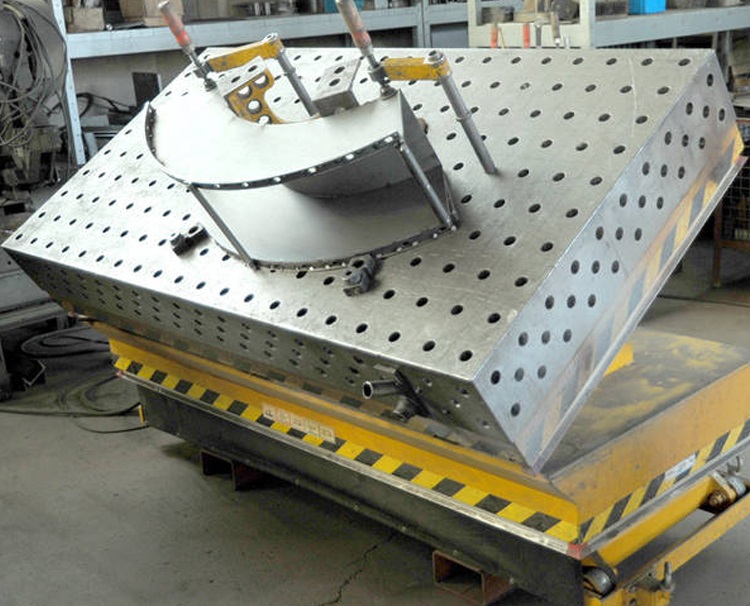

Teaching free programming welding robot is an advanced automation equipment that can automatically recognize and understand welding tasks through machine learning and artificial intelligence technology, and independently complete welding work. This type of robot does not require manual programming or teaching, but continuously improves welding quality and efficiency through machine autonomous learning and optimization.

The working principle of a teaching free programming welding robot usually includes the following aspects:

1. Image recognition: The robot automatically recognizes the position and shape of the welded workpiece, as well as the trajectory and depth of the weld seam, through high-resolution cameras and image processing algorithms.

2. Motion planning: Based on the identified information, the robot autonomously calculates the optimal motion trajectory and welding parameters, such as welding speed, welding angle, welding current, etc.

3. Autonomous control: The robot adjusts its position and posture in real time through high-precision servo systems and sensors, ensuring the stability and accuracy of the welding process.

4. Intelligent optimization: Robots continuously learn and optimize their welding processes through machine learning and artificial intelligence technology, improving welding quality and efficiency.

The advantages of teaching free programming welding robots include:

1. Efficiency: Robots can work continuously without being affected by fatigue and environmental factors, greatly improving welding efficiency.

2. High precision: The robot ensures the stability and accuracy of the welding process through a high-precision servo system and sensors.

3. Low cost: Robots can reduce labor costs and material waste, lowering production costs.

4. Strong scalability: Robots can weld workpieces of various shapes and specifications by replacing different tools and fixtures.

In short, the teaching free programming welding robot is an automated equipment with broad application prospects. It can improve production efficiency and product quality, reduce production and labor costs, and create more commercial value for enterprises.

Key words:

Online Consultation